Electronics & Industry

Low Pressure Molding

Today, the Low Pressure Molding technology is an integral part of the electronics industry and industry in general. With a wide variety of materials, the HENKEL GERMANY company provides solutions for many needs in the world of electronics and industry.

This world is characterized by large quantities, so that LPM SOLUTIONS allows an excellent price compared to competitors, because we discount the process of creating the final products for the customer.

With a phenomenal production time without the need for a curing room, it allows real estate savings (no need for a curing room, unlike the epoxy technology).

Possibility of immediate placement during the assembly process so that the critical path is significantly shortened.

The variety of materials - transparent and colored enables an affinity between the client's logo and the final product.

Transmission of quality transmission for the variety of advanced transmission methods.

The melting temperature of TECHNOMELT is around 180 degrees Celsius so that the electronic circuit is not damaged by the heat.

The masking capability indicated in the template allows manual masking on the motherboard.

Early planning makes it possible to spare the circuit with additional shielding parts that include a rigid structure, a unique sealing ring, screws, assembly time and final inspection.

The difficulty level of HENKEL materials allows great flexibility in the final application of the product.

Water resistance and creating adhesion between different factors in order to create maximum impermeability of sea water, chlorinated water and other liquids.

Heat sensitive batteries have successfully undergone TECHNOMELT injection together with the LPM technology. The low pressure allows controlled flooding of the components on the board and maintaining their properties.

The speed of production makes the assembly process fast, efficient and economical.

The lack of need to mask the electronic parts saves valuable work time.

The heat conductivity is effective for removing the heat produced in the electronic circuit and allows the integration of heatsinks in the production process.

Good resistance to the temperature differences that characterize the conditions of use in the final application of the product.

Henkel's variety of materials allows:

- Wireless transmissions.

- Fast heat removal.

- HEATSINK integration for controlled removal of heat

- Integration of end components that do not require a protective coating.

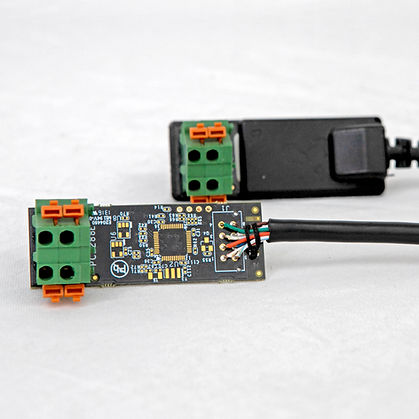

- Combination of cables with dedicated STRAIN RELIEF at the beginning of the cable when it is connected to the circuit.

Lightweight.

- With proper planning, the circuit can be protected with an extremely thin coating up to 1 mm according to its external outline, and alternatively, the circuit can be protected with a thickness so large as to create an external coating for the circuit.

- Protection against water pressure, high, low and changing ambient temperatures, damage and a challenging detergent environment.